Thermoset composites rule the modern age of manufacturing. They touch just about every major industry and are gaining market share by the week in the world of materials. Alongside the rise to prominence of thermosets are the means of production — namely, injection molding and 3D printing. Both methods are revolutionizing the manufacturing industry at their own pace. Injection molding is out in front strong, with 3D printing coming up fast behind.

A look at injection molding in 2020

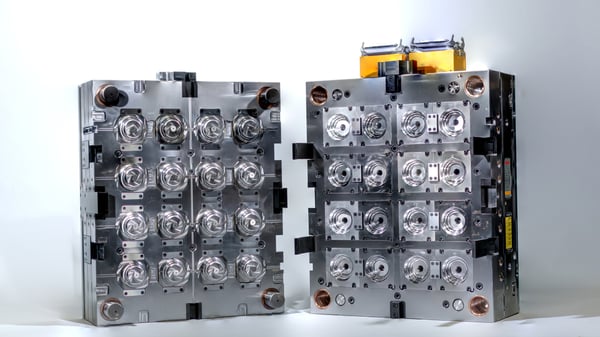

Injection molding has been a staple in composite manufacturing for decades (even as far back as the 1870s). And although the mode of production isn’t new, the innovations and trends driving it are. With the current advancements in tooling and technology, we’re experiencing a growth of more cavities per tool allowing us to be even more efficient. In the year ahead, injection molding is expected to experience fruitful advancement behind better technology and refined equipment. Expect advancements in injection mold speed, quality, and process control as well as better equipment and practices, resulting in decreased machine downtime.

Some of the heralding enablers behind these advancements include improved clamp and screw designs for molds, stack molds, and all-electric presses. There’s also the prospect of reduced composite preheating times for more efficient molding. Molding processing control software advancements will play a greater role in quality and process control.

For injection molding, the future is a coalescence of various improvements in hardware, software, composite sciences, and technician training. Numerous industries will continue to reap the benefits, including automotive, infrastructural, electrical, marine, industrial, and others.

What’s the future of 3D printing?

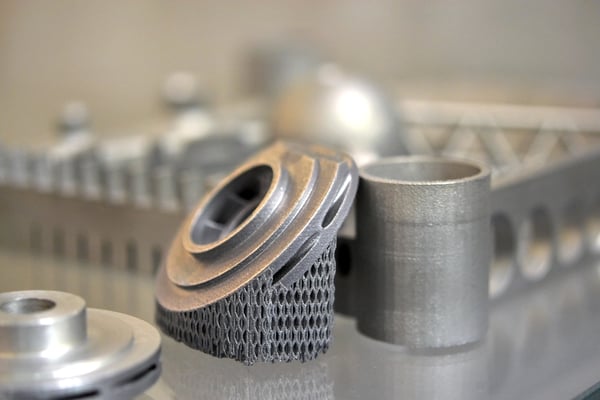

3D printing has lagged injection molding and languished in some industries. Today, however, it’s more relevant than ever. The push for better additive manufacturing technologies has taken root thanks to composites. And while it’s not quite ready to meet the demands of large-volume production, 3D printing is hard to beat for small runs and intricate tooling. In a nutshell, 3D printing is the new standard for rapid prototyping — and at Mar-Bal, we use it for just that, prototyping.

One industry where 3D printing has found new legs and broad opportunity is in electrical manufacturing. Standoff insulators, for example, vary in specification and application, requiring the ability to quickly prototype and produce iterations. 3D printing is aptly suited to the task. The concept is the same for a variety of other industries, fueling exponential demand for 3D printing in recent years.

The future of 3D printing is broad. There’s certain to be more of the same rapid prototyping in other industries — including automotive, consumer goods, marine, and agricultural industries — as well as new innovations that enable quicker, more versatile additive processes.

Dominance and demand in the age of plastics

As the capabilities of both injection molding and 3D printing improve, factors like cost, volume, speed, and complexity will continue to improve as well. As the age of plastics continues its reign, one thing is for certain — the options for how to produce the ideal product will only become more robust.

We utilize both technologies in pursuit of product and production optimization. Our molding capabilities and industry knowledge allow us to deliver best-in-class results to our customers. Contact us today through our website to learn more about how we can create value for you though our one-source model.