Any fabrication specialist can tell you that attention to detail is crucial. Neglecting the little things means the end product will suffer. A focus on detail goes beyond the product itself — quality products require flawless tooling. Taking the time to ensure the best possible tooling translates all the way through to the end product, saving costs, preventing problems, and guaranteeing excellence from start to finish.

Tooling is the first step

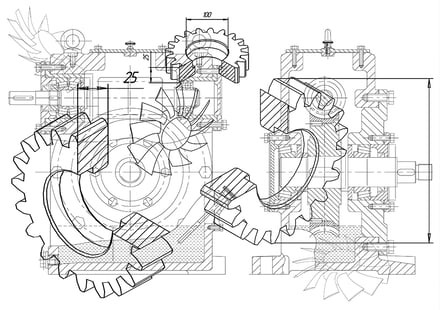

Before a product is mass produced, it requires a viable prototype. But this isn’t the first step in the process — tooling is. Even before the prototype, the concept must be brought to life from a schematic drawing. Using those specifications to develop dies is the first step in physical prototyping.

While it’s only a prototype at this stage, your product still benefits from precision tooling. Good tooling produces accurate prototypes, which lend themselves to thorough evaluation and testing. How can you be sure your product is going to perform as expected unless the prototype also holds up?

Good tooling during the prototyping phase also expedites this crucial first step. While there may still need to be iterations of a prototype before a final design is approved, tooling won’t be the issue.

The mindset behind proper tooling

Tooling requires the right mindset. It’s not just about taking customer specs and cutting the right die. It’s about ensuring that the variables match up to the application expectations for the product being prototyped. Here’s what to keep in mind during the tooling phase:

- What’s the purpose and scope of the product?

- What are the general specifications for the die?

- What tolerances need defining?

- What are the required materials?

- What’s the cost of those materials, along with die development?

- What’s the timeline for tooling development?

Assessing the entire scope of work is critical in tooling. It sets expectations for the integrity of the finished die, the efficacy of the prototype, and project management benchmarks such as cost and timeline.

In considering each phase, a quality tooling mindset will also strive for excellence and integrity. It’s not just “What are the specifications?” but also “Are the specifications correct?” Thinking consciously about every aspect of the project equates to prototyping with purpose.

Tooling is an opportunity for collaboration

Customers seek tooling not only to get their design prototyped and into production but also because it opens a line of communication. They may have the design expertise to conceptualize a product, but what they need help with are the nuances of physically creating it. Tooling is a chance to add value. Consider these questions:

- Can you recommend a specific bulk molding compound (BMC)?

- What’s the best source for materials?

- Is this product better for compression or injection molding?

- Where are there value engineering opportunities?

Decisions made during the tooling phase affect the prototyping phase, which dictates the integrity of the eventual product. Even at this earliest stage, collaboration is key. Taking a customer design and infusing it with thermoplastic molding expertise results in a collaborative tooling process that sets the tone for excellence in prototyping and beyond.

If your prototype project requires precise tooling, turn to the experts at Mar-Bal. Our industry-leading approach to tooling paves the way for rapid prototyping and high-caliber results. Speak with a project manager today regarding any tooling needs you have, and we’ll provide the oversight your project needs to progress smoothly. Reach us at 440-543-7526 or through our website.