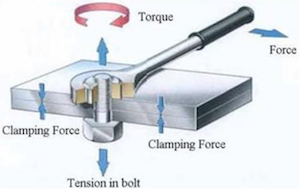

Torque is one piece of a larger puzzle that we call torsion. Torque is a twisting force that causes rotation, while torsion is the action of twisting or the state of being twisted, especially at one end of an object relative to the other. Most of us in the engineering field refer to torque when we want to know what the clamping force of a bolt is between two surfaces. When using torque for a standoff insulator, we are looking for the maximum amount of foot pounds (ft-lbs) or Newtons (N). The maximum amount tells us the greatest strength before failure. Once the maximum torque is found on a specific insulator through max failure testing, a safety factor is calculated and built into the torque strength specifications in order to give the highest possible strength without failure. One of the reasons torque is an important mechanical strength property is that if the torque value is too low, the bolt could potentially back out of the insert due to vibration or any kind of movement. If this happens, the parts can be damaged due to the lack of clamping force or, worse, have a total failure of the assembly. If the torque is too tight, the stress created on the bolt, insert, and their threads could be too much to withstand, and the bolt or insert could fail, resulting in a worst-case scenario where the assembly falls apart. To avoid this scenario in the installation of any bolt or insert, it is essential to know the specifications for torque strength.

Torque is one piece of a larger puzzle that we call torsion. Torque is a twisting force that causes rotation, while torsion is the action of twisting or the state of being twisted, especially at one end of an object relative to the other. Most of us in the engineering field refer to torque when we want to know what the clamping force of a bolt is between two surfaces. When using torque for a standoff insulator, we are looking for the maximum amount of foot pounds (ft-lbs) or Newtons (N). The maximum amount tells us the greatest strength before failure. Once the maximum torque is found on a specific insulator through max failure testing, a safety factor is calculated and built into the torque strength specifications in order to give the highest possible strength without failure. One of the reasons torque is an important mechanical strength property is that if the torque value is too low, the bolt could potentially back out of the insert due to vibration or any kind of movement. If this happens, the parts can be damaged due to the lack of clamping force or, worse, have a total failure of the assembly. If the torque is too tight, the stress created on the bolt, insert, and their threads could be too much to withstand, and the bolt or insert could fail, resulting in a worst-case scenario where the assembly falls apart. To avoid this scenario in the installation of any bolt or insert, it is essential to know the specifications for torque strength.